TOP > Improvement > Improvement7

Using grinding stones and machining center tool life span and reduce cost.

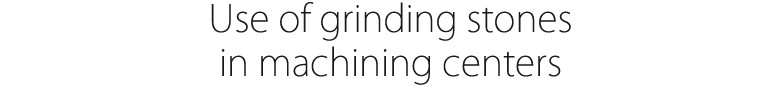

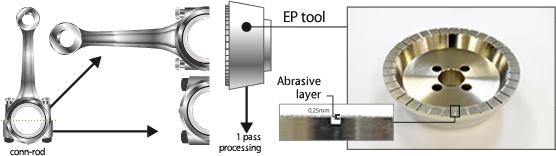

Traditionally, EP tools were used for grinding the matching surfaces of connecting rods in a machining centre. EP tools only have a single layer of abbrasive grains fixed on by electrodeposition, resulting in a small usable layer and poor tool life. Frequent tool replacement was required leading to issues with running cost, operating efficiencies and the need for large stock.

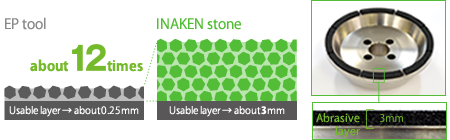

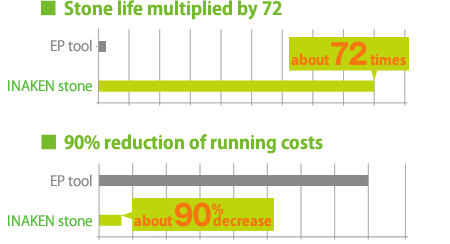

Grinding stones have a thicker abrasive layer than EP tools, with around 12 times the usable layer. This allows for usage over long time with little exchange of stones. As a result, the operating efficiency is improved and running costs are greatly reduced.

Compared to EP tools, there is no need to keep a large stock of grinding stones because of their long life.