TOP > Improvement > Improvement4

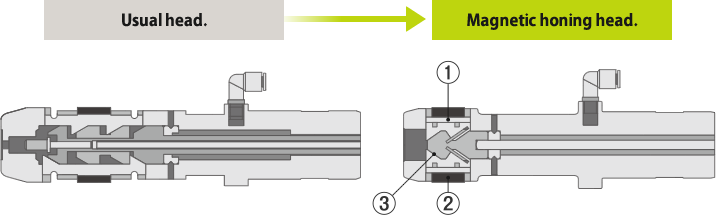

We rethink the honing head from the root to solve general problems in processing.

We can offer various kinds of KAIZEN proposals aproaching from every aspect together using rich know - how and reliable technologies.

KAIZEN point 1

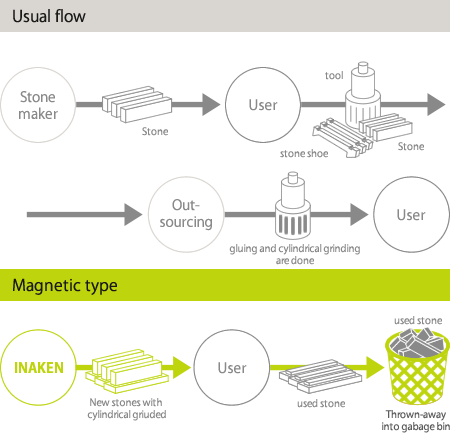

Previously, this customer was outsourcing the regluing and cylindrical grinding of replacement stones. We replaced their honing head with the magnetic type head so that operators can easily replace the stones themselves. With no more outsourcing and long delivery times, their production system became simple and smooth.

KAIZEN point 2

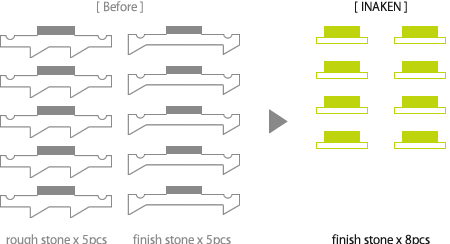

Previously, this customer was processing with 5 stones for roughing and 5 stones for finishing, using a total of 10 stones. We changed the process from having two parts into one process and reduced the number of stones from 10 to 8. Furthermore, we achieved a 20% cost reduction by changing the stone specifications.

KAIZEN point 3

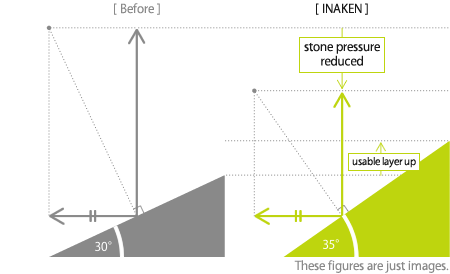

We changed the angle of the taper cone from 30 degrees into 35 degrees. By changing the angle, the pressure of the stone surface reduced and the accuracy was improved. Also the usable stone layer became larger, resulting in lower running costs.

| Contents | INAKEN |

|---|---|

| Stone cost | approx 65% reduction |

| Honing head cost | approx 30% reduction |

| Stone shoe cost | approx 70% reduction |

| Regluing and cylindrical grinding cost | approx 75% reduction |

| Total costs | approx 50% reduction |

With an over all improvement, a significant redution in cost was achieved.