TOP > Improvement > Improvement2

Achieved 6times faster manufacturing speed by changing to our honing stones

and manufacturing process. Reduced wastes and stabilized plating treatment.

| Workpiece | Large pipe for construction machine 225mm dia. S50C(HV600) |

|---|---|

| Machine | Honing machine (Hydraulic expansion) |

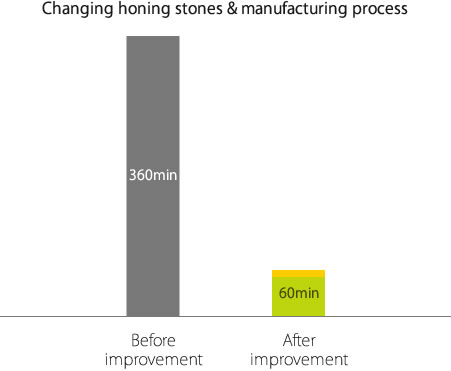

It took 6hours(360min) to grind one workpiece with WA stone before.

Only one workpiece was manufactured per day.

We achieved 6 times faster manufacturing speed by changing manufacturing process

from 1 to 2 with our grinding stones.

By using our products with low machine pressure, deformation of the workpiece was improved.

Manufacturing speed was able to be faster due to stable cutting ability of our grinding stones.

Due to small wear of our grinding stones compared with WA stone,

the amount of sludge from our grinding stone was 1/25 smaller.

By reducing wastes, grinding process was held with clean coolant.

Plating treatment after grinding process was stable due to stable cutting

ability of our grinding stones.

| Before improvement | After improvement | ||

| Stone specification | Conventional stone WA 400L | ATRYZ INAKEN (Rough) BN170 J P-1 | ATRYZ INAKEN (Finish) BN600 H P-1 |

| Stone size | 200L×19W×20T | 200L×12W×10T | 200L×12W×10T |

| Grinding amount(dia.) | 500um | 480-490um | 10-20um |

| Machine pressure | 25kg | 15-20kg | 10-15kg |

| Grinding speed | 27m/min | 36m/min | 36m/min |

| Grinding time | 360min | 55min | 5min |