TOP > Improvement > Improvement1

Selected a honing stone & a tool for water-soluble coolant

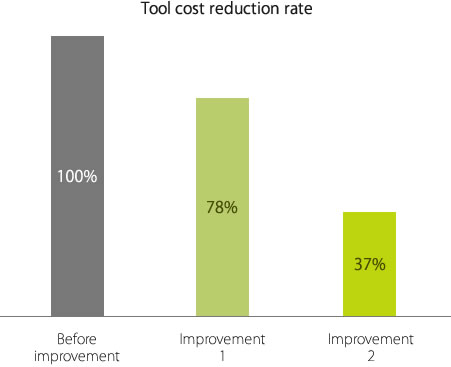

due to a change of oil coolant, and reduced tool costs by 37% as a result.

| Workpiece | Gear 32mm dia. SCM318(HRC58) |

|---|---|

| Machine | Honing machine (Hydraulic expansion) |

When coolant was changed from oil to water-soluble, grinding stone's

perfomance decreases. There was a case that stone life decreased 90%.

Specification of a grinding stone needs to be changed due to reduction

of its performance and life.

Compared with O-ring type honing head, there is no need to

keep spare holders because holders don't need for repeat orders.

Replacing grinding stones with ease because they are attached

with magnets.

Achieving stable grinding accuracy and reducing machine's work load

due to stiffness of Magnet type honing heads.

| Before improvement | Improvement 1 | Improvement 2 | |

| Description | Using oil coolant | Changing to water-soluble coolant | Changing to a magnet type honing head |

| Coolant | Oil coolant | Water-soluble coolant | Water-soluble coolant |

| Stone specification | Another company Metal honing stone | ATRYZ INAKEN BNX350 MB-13 P-5 | ATRYZ INAKEN BNX350 MB-13 P-3 |

| Stone size | 25L×3W×5T | 25L×3W×5T | 25L×4W×6.5T |

| Honing head | Oring-type | Oring-type | Magnet-type |

| Spare holders | 6 sets at least | 6 sets at least | 1 set ONLY |

| Tool life(pcs) | 1150 | 1480 | more than 3800 |

| tool costs | 100% | 78% | 37% |