TOP > Improvement > Improvement5

Provide stones with accurate cylindrical grinding.

Good product quality from the very beginning of stone replacement.

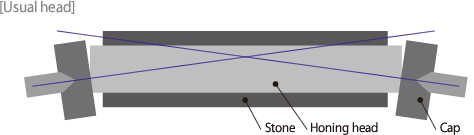

Usually in cylindrical grinding processes, caps are used on both ends of the honing head. It is very difficult to keep the tool centered due to the many joints created by assembling the honing head parts and caps. Moreover, the deviation becomes larger when a honing head gets warn out.

KAIZEN point 1

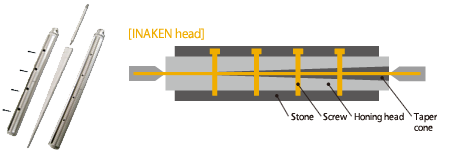

The INAKEN taper cone and head are able to be fixed with screws. Accurate cylindrical grinding is achieved by centering the axis on the taper cone screwed to the shoe.

KAIZEN point 2

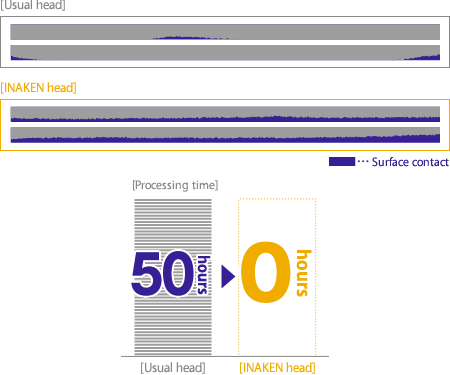

There are cases in which needing a original honing head was not able to start production due to the long surface contact process needed. Cylindricity of the product was poor with only the bottom end of the stone working despite 50 hours of surface contact processing.

INAKEN honing heads contact straight in the longitunal direction. Desired cylindricity is achieved from the first hole, making possible an immediate production start. With former honing heads, the bigger the dimensions of the stones, the more difficult it was to make surface contact. With the INAKEN Screw - Lock type honing heads, it becomes possible to achieve precise honing from the very first product.