TOP > Improvement > Improvement3

Scratch trouble happened frequently, so needed to rework.

Grinding quality was improved with our grinding stones and tools.

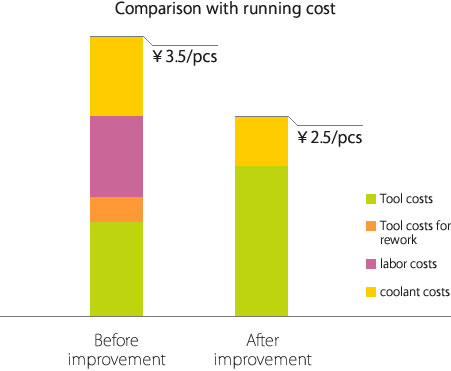

We achieved 30% running cost cut.

| Workpiece | Mastercylinder 20.64mm dia. |

|---|---|

| Machine | Honing machine (Mechanical expansion) |

HHoning stones are rounded by using a special jig.

So they fit workpiece bore, and achieve good grinding quality

from the first.

*GC stones need pre-processing with some workpieces.

It takes time. And GC stones are needed to replace frequently.

Our honing stones achieved 67times longer tool life, and reduced replacement frequency.

Tool life improves dramatically with our honing head

due to no contact on the surface of workpiece directly.

Lubrication improves because of enough space

between workpiece and our honing head.

So scratch and heat generation problem that relate to

chips build up of honing stones improve.

*A honing head with one stone touches the workpiece,

so it wears off easily. It tends to have troubles.

It need to be replaced to keep grinding quality.

| Before improvement | After improvement | |

| Stone specification | Conventional stone GC 600 | ATRYZ INAKEN SSD800 MB-5 P-7 |

| Stone size | 40L×4W×2.5T | 39.5L×3.5W×2T |

| Honing head | A honing head with one stone (contact with workpiece) | Our honing head with three stones (no contact with workpiece) |

| Tool life | 150 pieces | 9997 pieces |

| Replacement Frequency | 130 times/month | 2 times/month |

| Rework time | 7 hours/month | 0 hour/month |

| Costs of one workpiece | ¥3.5 | ¥2.5 |